Initial meeting

After getting to know each other, we will schedule a meeting with your project contact and, optionally, one of our last modellers and/or designers. You present your ideas and vision, either digitally or in person, and we will work with that. If you do not yet have a concrete idea, we will be happy to assist you and suggest design options based on the briefing.

You will be involved throughout the process and will receive regular updates on the status of your project.

You will be involved throughout the process and will receive regular updates on the status of your project.

Last

If you have an existing and reliable last, we will use it for the project. If you need to add a new model to your portfolio, our modellers will suggest suitable last models for your project requirements and optimise them to meet your needs.

Upper

Once the initial sample uppers have been created and the thicknesses have been determined, they can be sent to us. We prefer to measure your uppers in-house so that the dimensions and transitions can be used accurately in the design and the mould will close reliably.

First draft

This is where the creative process begins. We work our way through sketches and put what we have discussed on paper. The final choice of design is, of course, up to you.

If you come to our first meeting with a design brief or even a technical drawing, we will check it for technical feasibility and whether it is likely to meet the requirements profile (e.g. slip test, safety tests).

If you come to our first meeting with a design brief or even a technical drawing, we will check it for technical feasibility and whether it is likely to meet the requirements profile (e.g. slip test, safety tests).

2D design

Once you have decided on a design, we translate the concept into a final 2D drawing. After this step, you will receive all relevant dimensions in the form of a technical drawing.

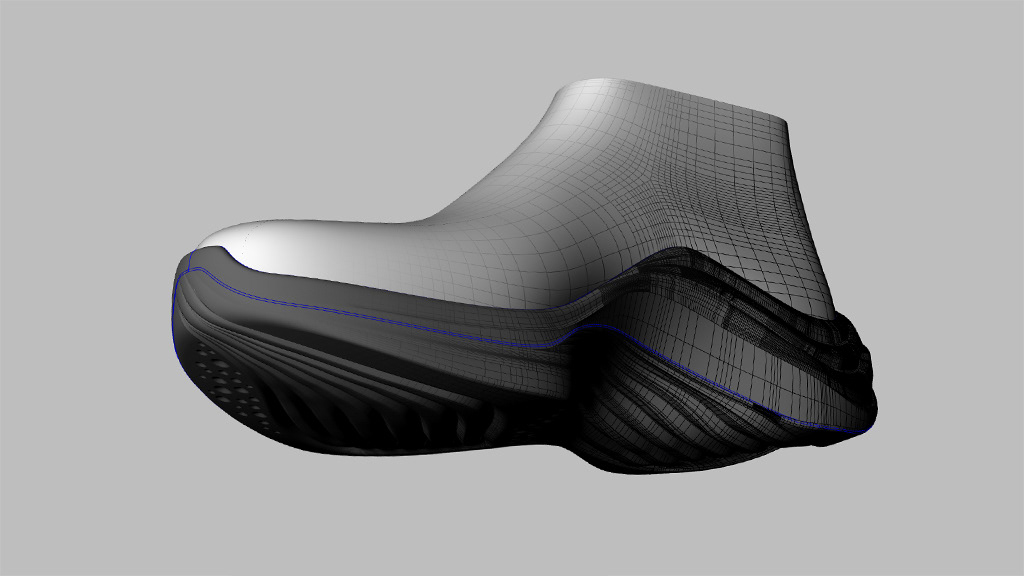

3D Design

Once the technical drawing has been approved, we begin the three-dimensional design of the sole. Following the 'rough to fine' principle, your new sole is created detail by detail. This step also ends with a detailed technical drawing and renderings to show the finished sole.

Protoyping

If you want to showcase your new development quickly, 3D printing is an option that gives you a realistic impression of the shape before the mould is completed, and is also great for visualising the sole with the upper.

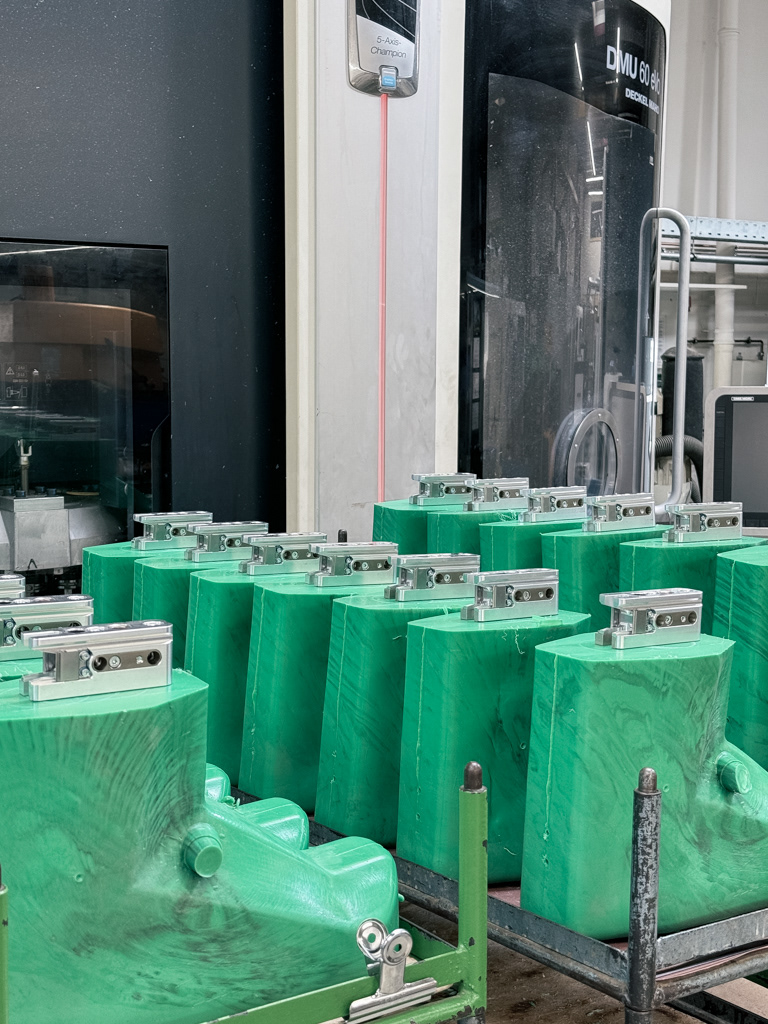

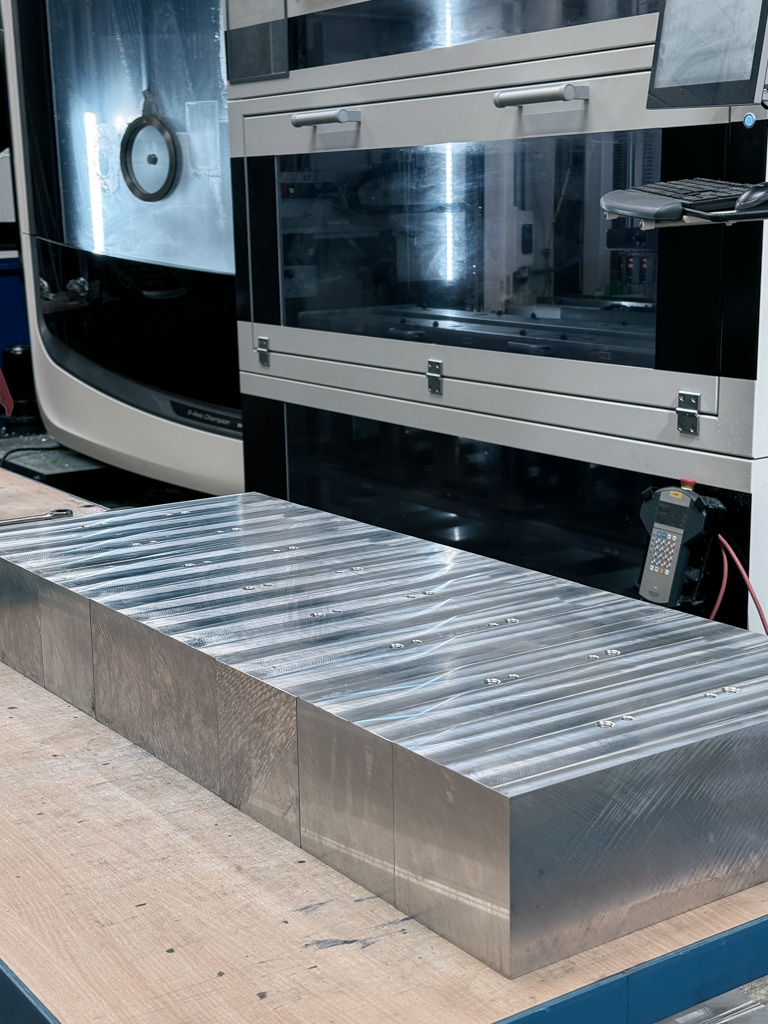

Mould making

When you are satisfied with your design, the mould making process begins with the production of the sample mould. If the moulding of the sole goes smoothly as planned, the series production of the desired sizes is carried out.

Service

If you wish, we can accompany you during your first mould approval and make sure that all the settings on your machine are correct, so that your sole can go into reliable series production.